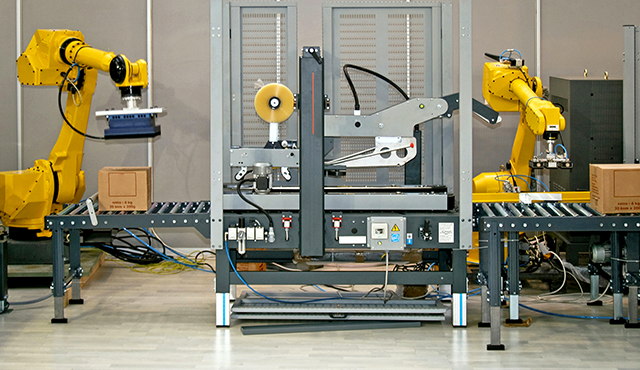

New guidance is now available on how to make packaging machines safe. This will provide much-needed assistance for machines used widely in the food and beverage industry, general manufacturing industry and warehousing/distribution industry. Australian Standards have published 8 new standards to provide guidance for different types of packaging machines:

- AS 4024.3401:2018 – Safety of Packaging Machines – Terminology and classification of machines

- AS 4024.3403:2018 – Safety of Packaging Machines – Form, fill and seal machines

- AS 4024.3404:2018 – Safety of Packaging Machines – Palletisers and depalletisers

- AS 4024.3405:2018 – Safety of Packaging Machines – Wrapping machines

- AS 4024.3406:2018 – Safety of Packaging Machines – Pallet wrapping machines

- AS 4024.3407:2018 – Safety of Packaging Machines – Group and secondary packaging machines

- AS 4024.3408:2018 – Safety of Packaging Machines – Strapping machines

- AS 4024.3410:2018 – Safety of Packaging Machines – General Requirements

These standards provide consistency with international practice because they are adoptions of the EN 415 series from Europe but be aware some of these standards are quite old. For example AS 4204.3403 is an adoption of a 1999 version standard and AS 4024.3404 is an adoption of a 1997 version standard. This means that many of the document references in these standards are out of date and some of the control measures are lacking when compared to today’s levels of safety, so be aware!

It is always a good idea to formulate the Category / Performance Level (PL) / Safety Integrity Level (SIL) requirement of safety functions based on the risk of the application using methods from current standards, thus using AS/NZS 4024.1501 for Category Selection, AS/NZS 4204.1503 for PL selection and AS 62061 for SIL selection.

It is also a good idea to always investigate what current industry practices are when selecting risk reduction measures. This can be done by referencing any guidance material published on your state WorkSafe website, observing new models of that machine type, exploring how other sites with similar machines provide safety, etc.

That being said, the new Packaging Machine Standards, do provide great assistance for risk assessment of packaging machines because many of the common hazards found on these machines are illustrated. The standards also provide good information on what types of safety measures can be utilised to reduce risk to an appropriate level.

Written by

Craig Imrie

Functional Safety Engineer (TUV Rheinland #3814/11, Machinery)

Safety Consultant

Rockwell Automation

LISTEN. THINK. SOLVE.